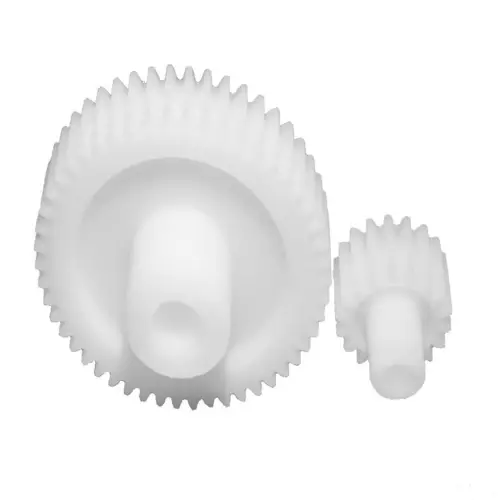

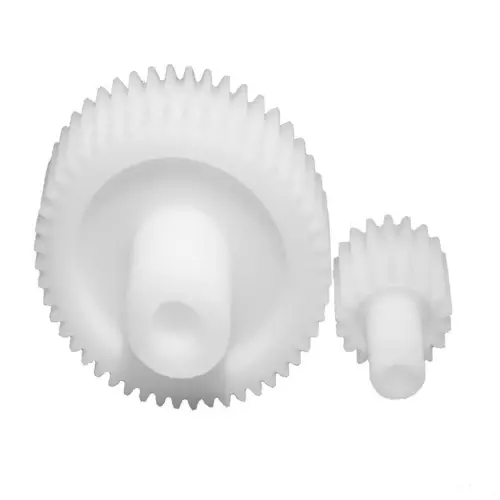

Plastic Spur Gears Expert Opinions and Their Relationship with Plastic Spur Gears

Plastic spur gears are widely used in various industries, and their popularity is increasing day by day. As plastic spur gears expert opinions suggest, these gears offer many advantages over their metal counterparts. In this article, we will explore plastic spur gears expert opinions and their relationship with plastic spur gears in detail.

Plastic Spur Gears Expert Opinions

According to plastic spur gears expert opinions, plastic spur gears have several advantages over metal gears. Firstly, plastic spur gears are lightweight and have minimal inertia. Secondly, they are quieter than metal gears and produce less noise during operation. Thirdly, plastic spur gears are non-corrosive and do not require any additional treatment to prevent corrosion. Fourthly, plastic spur gears can be manufactured in various colors, which is useful for color-coding in many applications. Finally, plastic spur gears have excellent resistance to chemicals and can withstand a wide range of temperatures.

Plastic spur gears expert opinions highlight that these gears are ideal for use in low-load and low-speed applications. They are commonly used in home appliances, toys, and office equipment. However, plastic spur gears expert opinions also state that they may not be suitable for high-load and high-speed applications.

Relationship between Plastic Spur Gears Expert Opinions and Plastic Spur Gears

Plastic spur gears expert opinions have a significant impact on the use of plastic spur gears. As experts suggest, these gears have several advantages over their metal counterparts, making them an attractive option for various industries. Moreover, plastic spur gears expert opinions have contributed to product development and improvements in plastic spur gears, making them more efficient and reliable.

Plastic spur gears are widely used in various industries, including home appliances, medical equipment, automotive, toys, and office equipment. They are available in different sizes, shapes, and materials, making them suitable for a wide range of applications.

Performance Characteristics of Plastic Spur Gears

Plastic spur gears have several performance characteristics that make them attractive for use in various industries. These characteristics include:

- Lightweight: Plastic spur gears are lightweight, making them ideal for applications where weight is a concern.

- Non-corrosive: Plastic spur gears are non-corrosive, making them suitable for use in harsh environments.

- Chemical resistance: Plastic spur gears have excellent resistance to chemicals, making them ideal for use in applications exposed to chemicals.

- Quiet operation: Plastic spur gears are quieter than metal gears, making them suitable for applications where noise is a concern.

- Wide temperature range: Plastic spur gears can withstand a wide range of temperatures, making them suitable for use in applications exposed to extreme temperatures.

Types of Plastic Spur Gears and Their Characteristics

Plastic spur gears are available in different materials, each with its unique characteristics. Some of the most common materials used for plastic spur gears are:

- Nylon: Nylon spur gears are strong and have good wear resistance. They are suitable for use in high-speed and high-load applications.

- Acetal: Acetal spur gears have excellent dimensional stability and are suitable for use in low-load and low-speed applications.

- Polyethylene: Polyethylene spur gears are lightweight and have excellent chemical resistance. They are suitable for use in applications exposed to chemicals.

- Polycarbonate: Polycarbonate spur gears have excellent impact strength and are suitable for use in applications exposed to high impact.

Applications of Plastic Spur Gears

Plastic spur gears are used in various industries, including:

- Home appliances: Plastic spur gears are used in various home appliances, such as washing machines, vacuum cleaners, and blenders.

- Medical equipment: Plastic spur gears are used in various medical equipment, such as infusion pumps and ventilators.

- Automotive: Plastic spur gears are used in various automotive applications, such as power windows and door locks.

- Toys: Plastic spur gears are used in various toys, such as remote-controlled cars and robots.

- Office equipment: Plastic spur gears are used in various office equipment, such as printers and scanners.

Future Trends and Opportunities for Plastic Spur Gears Products

Plastic spur gears are expected to gain more popularity in the coming years due to their advantages over metal gears. They offer several benefits, such as lightweight, non-corrosive, chemical resistance, and quiet operation. Furthermore, advancements in technology and materials are expected to lead to more efficient and reliable plastic spur gears.

To capitalize on the opportunities presented by the growing demand for plastic spur gears, manufacturers should focus on product development, quality control, and innovation. They should also maintain a strong relationship with their suppliers and customers to ensure a steady supply of materials and a reliable market for their products.

Choosing the Right Plastic Spur Gear

Choosing the right plastic spur gear involves several factors, including:

- Clarifying needs: Understanding the requirements of the application and the environment in which the gear will operate.

- Material selection: Choosing the appropriate material based on the requirements of the application.

- Design optimization: Designing the gear to optimize performance and efficiency.

- Supplier and after-sales service: Choosing a reliable supplier who can provide quality products and after-sales service.

- Cost-effectiveness: Choosing a gear that offers the best value for money.

- Quality control: Ensuring that the gear meets all quality standards and specifications.

How to Maintain Plastic Spur Gears

Maintaining plastic spur gears involves several factors, including:

- Regular equipment checks: Regularly inspecting the gear to ensure its proper functioning.

- Cleaning and corrosion prevention: Cleaning the gear regularly and applying corrosion prevention methods to ensure its longevity.

- Lubrication and maintenance: Lubricating the gear regularly and maintaining its components to ensure smooth operation.

- Replacement of worn parts: Replacing any worn-out parts to avoid damage to the gear.

- Improvement and upgrading: Continuously improving and upgrading the gear to maximize its efficiency and performance.

Why Choose Us?

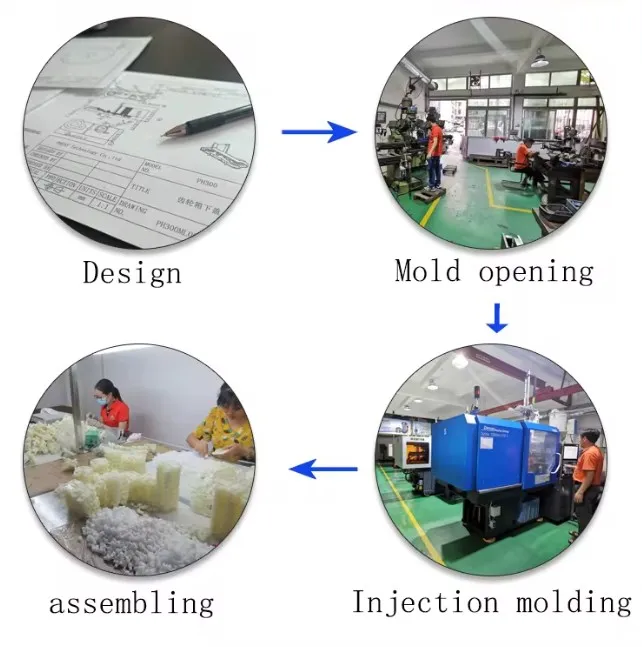

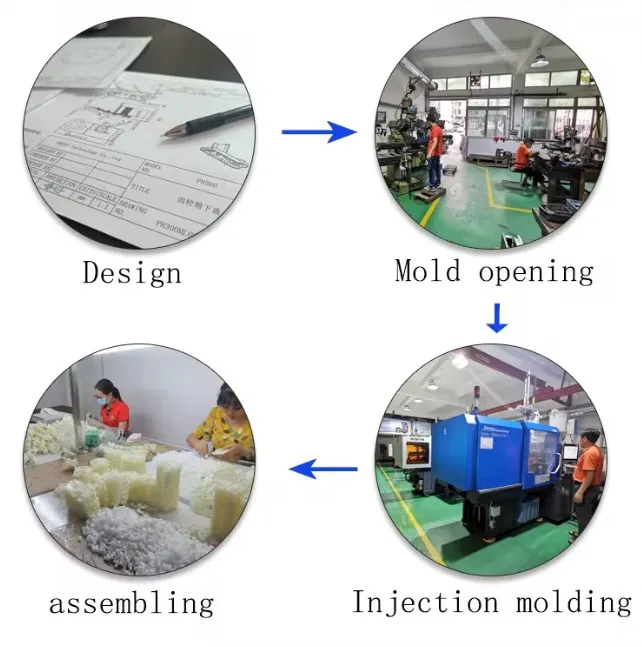

Our company specializes in the production and sales of plastic spur gears. We offer several advantages over our competitors, including:

- Quality products: Our plastic spur gears are made of high-quality materials and undergo strict quality control to ensure their reliability and performance.

- Customization: We offer customized plastic spur gears to meet the specific requirements of our customers.

- Competitive pricing: Our plastic spur gears are priced competitively, offering excellent value for money.

- Reliable after-sales service: We offer a reliable after-sales service to ensure the satisfaction of our customers.

- Expertise: Our team consists of experts who have extensive experience in the production and sales of plastic spur gears.

Contact us today to learn more about our products and services.

Q&A

Q1: Are plastic spur gears better than metal gears?

A1: Plastic spur gears offer several advantages over metal gears, such as lightweight, non-corrosive, chemical resistance, and quiet operation. However, they may not be suitable for high-load and high-speed applications.

Q2: What are the materials used for plastic spur gears?

A2: Some of the most common materials used for plastic spur gears are nylon, acetal, polyethylene, and polycarbonate.

Q3: What are the applications of plastic spur gears?

A3: Plastic spur gears are used in various industries, including home appliances, medical equipment, automotive, toys, and office equipment.

Q4: How to choose the right plastic spur gear?

A4: Choosing the right plastic spur gear involves several factors, including clarifying needs, material selection, design optimization, supplier and after-sales service, cost-effectiveness, and quality control.

Q5: How to maintain plastic spur gears?

A5: Maintaining plastic spur gears involves regular equipment checks, cleaning and corrosion prevention, lubrication and maintenance, replacement of worn parts, and improvement and upgrading.

Author: Dream